Cleaning chemicals are used in almost every workplace, from offices and schools to factories and hospitals. Many workers use them daily, often as part of routine tasks like disinfecting surfaces or restocking supplies.

However, without precautions, even familiar cleaning chemicals pose serious health risks, including skin burns, breathing problems and eye injuries.

This guide outlines what workers need to know to use cleaning chemicals safely.

Key Takeaways

- Cleaning chemicals are a leading cause of work-related skin and respiratory conditions.

- Risks include burns, eye damage, dermatitis and asthma.

- Safe use relies on reading labels, storing products correctly, diluting with care and wearing suitable personal protective equipment.

- By law, employers must implement control measures to reduce the risk of harm caused by hazardous chemicals.

Why Safe Use of Cleaning Chemicals at Work Matters

Employers have a legal duty to protect anyone who may be exposed to hazardous substances, including cleaning chemicals.

Under the Health and Safety at Work etc. Act 1974, they must ensure the health, safety and welfare of their employees. The Control of Substances Hazardous to Health (COSHH) Regulations 2002 require them to assess and control the risks that hazardous substances pose.

Effective control includes ensuring cleaning chemicals are handled and applied safely. Employers must provide suitable products, supply and maintain personal protective equipment (PPE), and train workers in how to use that equipment correctly. Critically, they must also communicate the risks associated with each chemical and the control measures needed to stay safe.

Missing any of these steps risks non-compliance. Failing in your health and safety duties can result in enforcement action, fines or prosecution – and allow the people carrying out the work to suffer avoidable harm.

COSHH Training

Our COSHH Training course provides basic awareness to trainees to help them identify the dangers and adopt safe working practices whilst working with hazardous substances, as well as, comply with the law.

Types of Cleaning Chemicals and Their Risks

Understanding the main types and their associated risks is key to using cleaning chemicals safely.

Bleaches

Bleaches contain powerful oxidising agents such as sodium hypochlorite. These can burn the skin and eyes on contact and also irritate the lungs if inhaled. Mixing bleach with acids or ammonia releases toxic chlorine gas, which can cause coughing, chest pain, or serious breathing difficulties.

Disinfectants and Sanitisers

Disinfectants often contain alcohols or quaternary ammonium compounds (quats). Quats are recognised asthmagens under COSHH, meaning they can cause occupational asthma after repeated exposure.

Handling disinfectants without protective gloves can also result in irritation or dermatitis, a painful skin condition characterised by redness, cracking, or blisters.

Degreasers and Solvent Cleaners

Degreasers typically use solvents such as butanol or acetone to dissolve oils and fats. These vapours can irritate the eyes and airways. In high concentrations, they can even affect the nervous system, causing light-headedness or drowsiness. Direct contact can also strip the skin of natural oils, leading to cracking or dermatitis.

Descalers and Acid-Based Cleaners

Descaling products contain acids like hydrochloric or phosphoric acid, which remove limescale and mineral deposits. They can cause painful burns to the skin or eyes and release harmful fumes that irritate the throat and lungs. Using these products safely requires appropriate gloves, eye protection, and ventilation.

Best Practices for Using Cleaning Chemicals Safely at Work

Before deciding how to store, handle, or use cleaning chemicals safely, every employer must first complete a risk assessment.

This risk assessment must identify:

- All hazardous cleaning chemicals

- Who could be harmed

- How they might be harmed

- Control measures needed to prevent this harm

The control measures below represent common good practice, but won’t necessarily be relevant to your workplace. The employer is ultimately responsible for deciding which control measures are needed and sufficient, based on the findings of their risk assessment.

Read Labels and Safety Data Sheets Before Use

Every cleaning product in Great Britain must carry a label under the Classification, Labelling and Packaging (CLP) system. These labels explain the hazards of cleaning chemicals and how to use them safely.

A label includes four key parts:

- Hazard pictograms – also known as COSHH symbols, show the type of danger, such as a flame for flammable or a hand being corroded for corrosive.

- Signal words – either Danger for high-risk products or Warning for lower risks.

- Hazard statements – plain-language descriptions of the risk, such as Causes serious eye damage (H318). This indicates permanent harm, which is more severe than Causes eye irritation, where symptoms are temporary.

- Precautionary statements – clear instructions for safe use, such as Wear protective gloves or Keep away from open flames.

Some products also come with a Safety Data Sheet (SDS). Suppliers must provide these for hazardous substances. An SDS explains the product’s ingredients, the risks it poses, how to store it, the protective equipment you need, and what to do in an emergency. If your product does not have one, your employer must request it from the supplier.

Reading the label and SDS before use ensures you know the risks and how to protect yourself.

Store Chemicals in the Right Way

Every workplace that uses cleaning products must have safe storage procedures. Improper storage is one of the most common causes of chemical accidents.

The safest option is to keep products in their original containers. These containers are designed to hold the chemical safely and carry the correct label. Decanting into bottles or jars meant for food or drink creates a serious risk of accidental ingestion.

Chemicals should be locked away if children, patients, or other vulnerable people could reach them. They must also be stored so that incompatible products are kept apart. For example:

- Bleach and acids must never be stored together. If mixed, they release chlorine gas, which burns the lungs.

- Bleach must also be kept away from amine-based products such as quaternary ammonium compounds (QACs). Mixing these creates toxic vapours that can harm the respiratory system.

Every workplace should have a storage plan to follow. This may include using fire-resistant cabinets for flammable products or acid-resistant shelving for corrosive products. Sticking to these rules reduces the risk of spills, dangerous reactions, and exposure.

Handle and Dilute Chemicals Safely

How you use a cleaning chemical is just as important as which product you choose. Safe handling reduces the risk of burns, eye injuries, and breathing problems.

- Follow the label or Safety Data Sheet. SDS explains exactly how much water is needed to dilute the product. Too much chemical increases the chance of harmful fumes or burns. Too little means the product will not clean effectively.

- Never mix products unless the label confirms it is safe. Mixing bleach with acids produces chlorine gas, which damages the lungs. Mixing bleach with some disinfectants also creates toxic vapours.

- Use clean, dry tools such as jugs or scoops. Wet or contaminated tools can trigger unexpected chemical reactions.

- Keep running water nearby. Immediate rinsing is the quickest way to reduce harm if chemicals splash onto skin or eyes.

- Plan for ventilation. Open windows where possible to let fresh air in. For higher-risk tasks, workplaces may provide Local Exhaust Ventilation (LEV), such as extractor fans or hoods placed close to the task, to pull vapours away from workers.

Wear the Right Personal Protective Equipment (PPE)

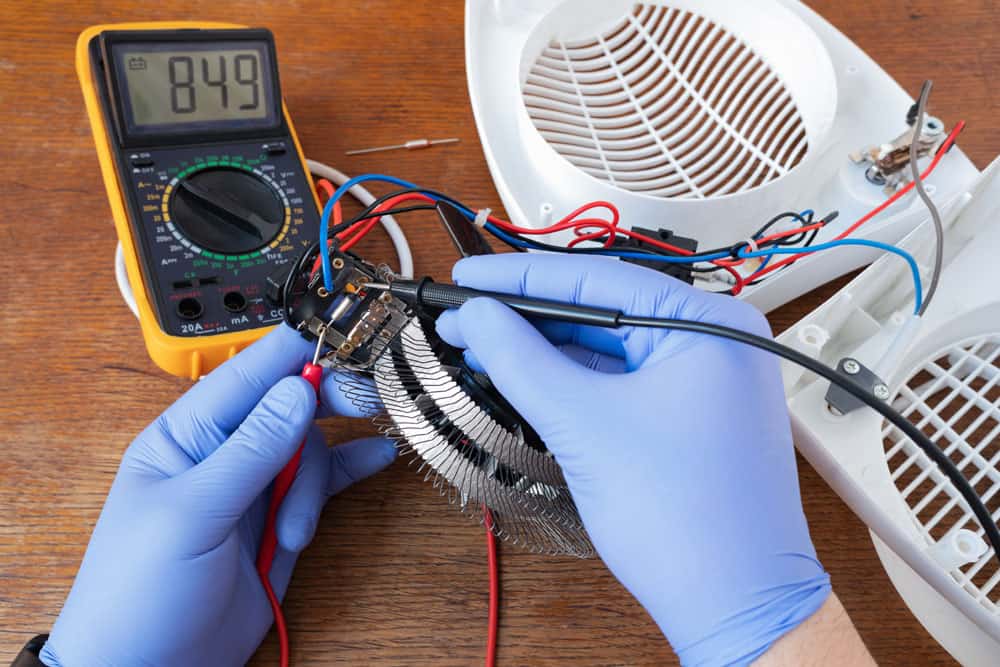

The right Personal Protective Equipment (PPE) reduces the risk of chemical exposure during cleaning tasks. Each type of PPE is designed to protect against specific hazards and must be used correctly.

- Gloves protect hands from direct contact with chemicals. Different glove materials offer different levels of resistance, so the type must match the chemical being used. Gloves also have a “breakthrough time,” which is how long they protect before the chemical passes through. Replace gloves before this time is reached.

- Eye and face protection stops chemicals from reaching the eyes or face. Goggles provide a tight seal around the eyes, while face shields cover the whole face for larger splash risks. The right choice depends on the task.

- Protective clothing prevents chemicals from soaking through clothes and reaching the skin. Options include aprons, jackets, or chemical-resistant suits.

- Respiratory protection prevents harmful vapours or dust from being inhaled. Masks and respirators must fit properly and use the correct filter for the chemical involved.

Learn More About Using Cleaning Chemicals Safely

If you work with cleaning products, you need to understand how to handle them safely. The COSHH Training for Cleaners course explains the key risks of cleaning chemicals and shows you how to control them.

The training is built around the COSHH Regulations and tailored to everyday cleaning tasks. It covers how to identify health hazards, prepare and store chemicals, and use the right PPE. You will also learn why hand hygiene and proper glove use are critical, how pH levels affect different products, and which chemical combinations are unsafe.

The course is fully online, CPD-certified, and takes just 35 minutes to complete. On passing the assessment, you receive a recognised training certificate that is valid for three years.

This training gives you the knowledge to protect yourself, your colleagues, and the people around you while meeting the requirements of safe cleaning practice.